How to Refinish Baseboard Trim

Trim Repair: How to Set up and Revive Trim

Updated: Jun. 19, 2019

Renew tiresome trim in one weekend.

Renew the lustrous appearance of stained and varnished woodwork without the messy stripping process. We show you how.

Yous might also similar: TBD

- Time

- Complexity

- Cost

- A full day

- Beginner

- $51–100

Step 1: Start with a thorough cleaning

You can dramatically meliorate the advent of stained baseboards and varnished woodwork without all the piece of work and mess of a consummate stripping and refinishing chore. We'll show y'all a much easier process here—and yous may even be able to eliminate some steps if your woodwork is in better shape than ours. Just gather the supplies in a 5-gallon saucepan and tackle the renewal project one window or door at a time whenever yous have a few spare hours. Start in a corner or in an inconspicuous surface area—better to acquire from your mistakes there than on the front door.

The first step in renewing your woodwork and stained baseboards is cleaning information technology to remove grease and grime and create a contaminant-free surface for the new finish. Wash the woodwork with a TSP substitute. Use just enough cleaner to wet the surface. Scrub with a sponge dipped in the cleaning solution. Then rinse with a sponge and clear water and wipe off the wood with a dry out rag.

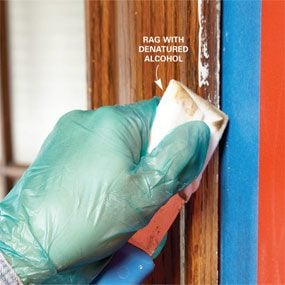

If there'southward pigment slopped onto the edges of your trim or spattered on the surface, now's the time to make clean it off. A rag dampened with denatured alcohol will remove most paint spatters (Photo 1). Alcohol won't harm most finishes, only it will deliquesce shellac. Don't worry if some of the finish comes off. You can touch it up afterward (Photo 7). Protect the walls with masking tape to prevent the alcohol from damaging the pigment. For tougher pigment spatters, utilize a fine synthetic abrasive pad (such as a 3M Wood Finishing Pad) dipped in denatured alcohol.

Stride 2: Scrape and sand badly damaged areas

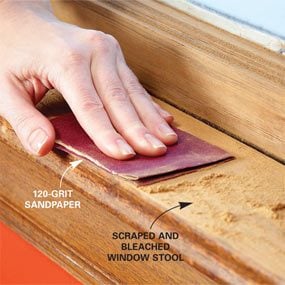

Window stools and other areas exposed to wet and sunlight may demand to be completely refinished. In spots such as these where the wood is discolored and the end worn away, yous'll get the best results by scraping and sanding to expose bare forest (Photos 2 and four).

If the wood has dark water stains that scraping and sanding won't remove, you can remove them with oxalic acid (Photo 3).

Caution: Clothing protective gear, including goggles, condom gloves and a long-sleeve shirt, when y'all work with oxalic acid. Mix the oxalic acid in a plastic container. Add together 1 oz. of oxalic acid powder (about two tablespoons) to ane cup of hot h2o and stir it until the powder dissolves. Then brush the solution onto the stain with a disposable sponge castor and permit it piece of work for 20 minutes. Y'all can repeat the procedure to further lighten the stain. Wipe the bleached wood with a sponge and clear water. Then neutralize the oxalic acrid past applying a solution of 3 tablespoons of borax to 1 gallon of water with a sponge. Finally, rinse the bleached wood with water again and let it dry out overnight. Then sand it with 120-grit followed by 180-grit sandpaper (Photograph 4) and stain it to match the rest of the woodwork.

Footstep three: Roughen the finish and fill up small holes

To brand new finishes stick well, slightly roughen the sometime finish kickoff (Photograph 5). Synthetic finishing pads are the best choice considering they adapt to profiles and aren't as aggressive equally sandpaper. Buy medium and fine and experiment in an inconspicuous area. Utilise the pad that roughens the end without removing whatever stain.

Fill up holes left by nails or screws with soft wood putty. Woods putty is available in many colors that you can blend for a perfect match. Awarding is easy. Yous just push button it into the pigsty and wipe it off (Photo 6). In that location'southward no sanding required. Buy several shades of putty, ranging from dark to low-cal, that are similar to the color of your trim. Then mix them to match the wood surrounding the hole. Push button the putty into the hole and wipe off the excess with your fingertip. Then remove residue from effectually the pigsty by wiping over it with a clean rag. If your woodwork has filled blast holes that have darkened and no longer lucifer, pick the old filler out and replace it with soft putty. Purchase water-based putty if yous plan to utilize water-based polyurethane.

Step 4: Apply stain to hide dings and scratches

Completely refinishing the expanse may exist the only way to brand flawless repairs to badly damaged doors, windows and moldings. But y'all tin greatly improve the overall appearance of worn or damaged woods with less drastic measures.

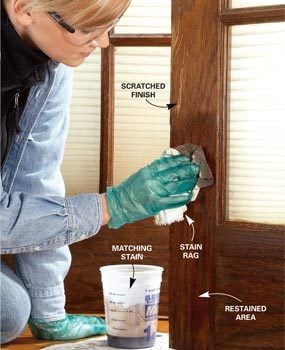

Disguise big areas where the stain is worn away by dabbing stain over the light areas to blend them in. The patched area may not match exactly, but at least the spot will exist less obvious. Or simply wipe the surface of the wood with a rag dipped in stain to fill in pocket-sized scratches and imperfections—you'll see a large comeback (Photograph vii). Wipe the stain on. And so wipe off the excess with a clean rag. Permit the stain to dry overnight before you apply the terminate.

Ane of the trickiest parts of a forest restoration project is finding stain to match. You can pry off a small piece of trim and ask the paint department to mix stain to friction match. Some paint stores and habitation centers offer inexpensive sample packets of stain. You tin can cull several samples that are close to the color of your wood and experiment in a subconscious area to find the best colour match. And so buy a larger container. Some other approach is to purchase two or iii cans of stain that are close to the color of your woodwork and mix them to become the correct color. Employ an eyedropper and disposable plastic cups to mix small batches until you lot get the proportions correct. Keep notes and then you can reproduce the results in a larger batch.

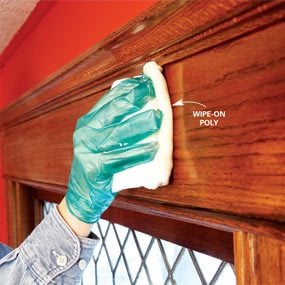

Footstep 5: Apply the fresh finish

The final step in your trim renewal project is to use a fresh glaze of finish. Wipe-on polyurethane is a practiced option because information technology'southward fast and easy to utilise. You only wipe it on with a soft rag and let it dry. Each glaze is very thin and dries quickly. Y'all can recoat in two or 3 hours if yous desire a thicker terminate for extra protection. Several coats of wipe-on polyurethane are required to equal the thickness of ane coat of brushed-on varnish, just it's easier to get a smooth, drip-free finish with wipe-on poly.

Fold a cotton rag to create a pad. Then dip an edge of the pad into a container of wipe-on polyurethane and printing information technology against the side to wring out the backlog. Wipe the polyurethane onto the wood in long strokes in the direction of the forest grain as you would if you were using a brush.

For window stools or other trim exposed to sunlight, consider using spar varnish. Spar varnish has built-in ultraviolet protection and is more flexible, so it holds up better in areas exposed to sunlight and water. Experiment on a scrap of trim or in an inconspicuous area to see if the slightly bister tint darkens the color too much. When you've completed all of the steps higher up, your woodwork will expect like new and be protected by a fresh layer of finish. If you don't have time to do an unabridged room from beginning to end, just tackle one door or window whenever you have a few spare hours. You'll be washed with a room before you lot know it.

Circular Upward Your Supplies

You'll need the materials and supplies listed in "Additional information" below for a basic forest renewal projection, including several for refinishing window stools and removing stains. Most of the tools and supplies are available at paint stores, full-service hardware stores and home centers. Visit an art supply store for the artists' markers. Oxalic acid is available online at rockler.com or at woodworking stores and some hardware stores and lumberyards.

Faux Woods Patch

Dings and dents too big to fill up with soft putty present a unique challenge. If you can't supersede the woods, the adjacent best thing is to patch the damage with filler and color the patch to friction match. Use hardening-type filler like Durham'south Rock Hard Water Putty. Utilize the filler carefully with as trivial excess as possible to minimize sanding. Permit the filler dry and sand it polish, being conscientious to avoid sanding away the end on the surrounding wood. Then apply felt tip markers to "paint" the patch to match (photos beneath). Art supply stores are the best source of markers—you'll find endless shades of brown. Almost other stores carry only one or two. The repair won't be perfect, only you lot may be surprised by how inconspicuous it is from a altitude.

Required Tools for this Projection

Have the necessary tools for this DIY projection lined upwards before you start—you'll salve fourth dimension and frustration.

Rubber gloves

Required Materials for this Projection

Avoid last-minute shopping trips by having all your materials ready alee of fourth dimension. Here'due south a listing.

Originally Published: January 07, 2019

Source: https://www.familyhandyman.com/project/trim-repair-how-to-fix-and-revive-trim/

0 Response to "How to Refinish Baseboard Trim"

Post a Comment